A six-axis hot-dip galvanizing manipulator is used as an example in this essay. Mechanically, the six-axis robotic arm is structurally designed with a 6-degree-of-freedom space coordinate system. All of the six axes work with servo motors with reducers, and finish corresponding actions with servo driver controlled by Karnop Robot control system.

I.

Introduction

With the improvement of the

automation of industrial production lines, Industrial manipulators are

frequently used in production processes such as painting, packaging, welding,

and assembly to replace manual labor in harsh environments. Here, a six-axis

hot-dip galvanizing manipulator is used as an example for description.

Mechanically, the six-axis robotic arm is structurally designed with a

6-degree-of-freedom space coordinate system. All of the six axes work with servo

motors with reducers, and finish corresponding actions with servo driver controlled

by Karnop Robot control system.

2. System

Introduction

1. Characteristics of six-axis

industrial manipulator:

(1) High speed:

Lightweight devices and high-power micro motors are used to increase the speed,

thereby shortening the cycle time and improving production efficiency.

(2) High precision: The

six-axis industrial manipulator adopts high-quality, high-performance harmonic

reducer so that it can be repeatedly positioned in the running project to

ensure accuracy.

(3) Good sealing performance:

the shafts are completely sealed, suitable for use in harsh environments with

high sealing requirements such as dust, oil stains, and harmful gas liquids.

(4) Small in size but can

handle heavy load.

2. Advantages of six-axis

industrial manipulator:

(1) The six-axis

industrial manipulator responses quickly. The robot does not stop or rest

during the operation, and improves the efficiency of automated production.

(2) The six-axis

industrial manipulator has high accuracy and high-quality impact, which ensure

the product quality.

(3) The usage of six-axis

industrial robots can reduce labor costs and waste of raw materials.

(4) It is possible to

adapt to the production of different work pieces by modifying the program,

shortening the product replacement cycle, and investing in application

equipment.

(5) Replace workman, work

in harsh and hazardous environments.

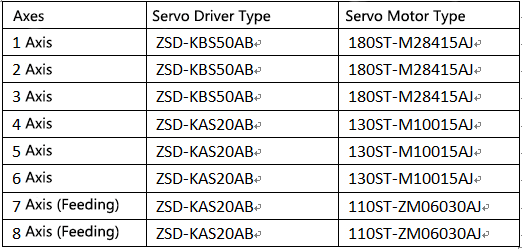

3.

six-axis manipulator requirements for servo

The six-axis galvanized

manipulator is mainly composed of 6 sets of servo drives and motors combined

with reducers to complete the positioning and rotation of the manipulator.

Besides, there are 2 sets of servo drives and motors responsible for feeding. Among

them, 1, 2, and 3 axes are composed of Zhishan ZSD-KBS50AB with 180ST-M28415AJ

motor, and 4, 5, 6 axes are composed of Zhishan ZSD-KAS20AB with 130ST-M10015AJ

motor. The 7 and 8 axes are composed of ZSD-KAS20AB with 110ST-ZM06030AJ motor.

The servo drives all work in position mode, and the robot control system sends

control signals to servo drives to drive the motors to complete the

corresponding actions.

The working scene is shown

in Figure 1:

Figure

1

4.

Introduction of industry matching performance

The host computer is

connected to the servo drive control site. The control mode is pulse +

direction in position mode. The host computer sends a position command to the

servo drive and the servo drive motor completes the corresponding action. The

control wiring is defined as follows:

5. Application

of Zhishan servo on the six-axis manipulator

1. Servo drive and motor

configuration

2. Related parameter

settings

(1) Electronic gear ratio

Control resolution

according to specific application requirements

(2) Speed loop

integral time constant

When this parameter is

reduced, the response can be faster and the speed control error can be less.

However, if the setting is too small, vibration and noise are likely to occur. The

parameter is larger, the rigidity is worse.

(3) Speed loop

proportional gain

When this gain value is

increased, the response can be faster. But if the setting is too large, it is

easy to produce vibration and noise

(4) Position loop gain

Increase the position loop

gain to speed up the system response. Reduce positioning error and shorten

positioning time. However, excessive vibration caused mechanical vibration and

a system position to overshoot.

(5) Rotational inertia

ratio

Ratio of load inertia to

motor shaft inertia

(6) low-frequency jitter

Prone to rapid start and

stop the robot arm end is positioned so that the prolonged positioning influence

production efficiency, the built-in servo control debouncing by PA004 number

parameter bottom jitter suppression function is enabled, by PA413 and PA414

disposed jitter Frequency and damping.